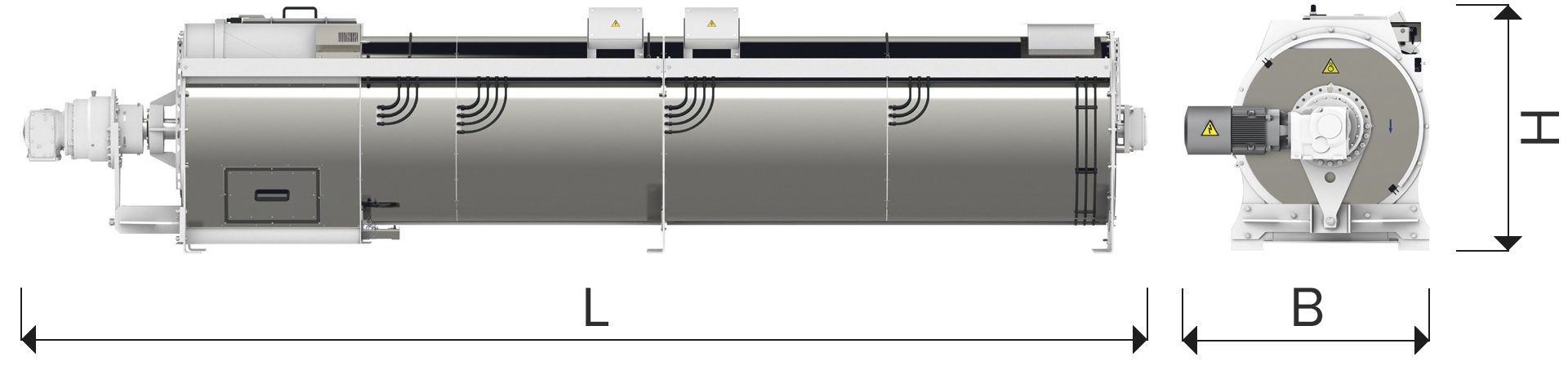

Long-term conditioner

Description

Conditioner is used for the heated product retention in order to effectively destroy the pathogens.

- Reliable and safety design with automatic temperature control and automated control system excluding human factor. Regulated timeframe of thermal treatment – from 60 to 240 seconds.

- Two processing stages:

- product treatment with saturated steam;

- product heating under gentle temperature conditions.

- High degree of starch decomposition, devastation of pathogenic germs.

- Reduction of the pellet mill die wear and maximum pellet strength.

Specifications

| L, mm | B, mm | H, mm | ||

| KDV-1600 | 5390 | 955 | 1160 | |

| KDV-3000 | 6325 | 1340 | 1375 | |

| KDV-4500 | 8535 | 1435 | 1375 |

| Work volume, m³ | Capacity, m³/h | Electric motor power, kW | Heater power, kW | Weight, kg | |

| KDV-1600 | 1,55 | 20 | 4,0 | 14 | 2000 |

| KDV-3000 | 3 | 40 | 7,5 | 19,5 | 2480 |

| KDV-4500 | 4,47 | 60 | 15 | 24 | 3230 |